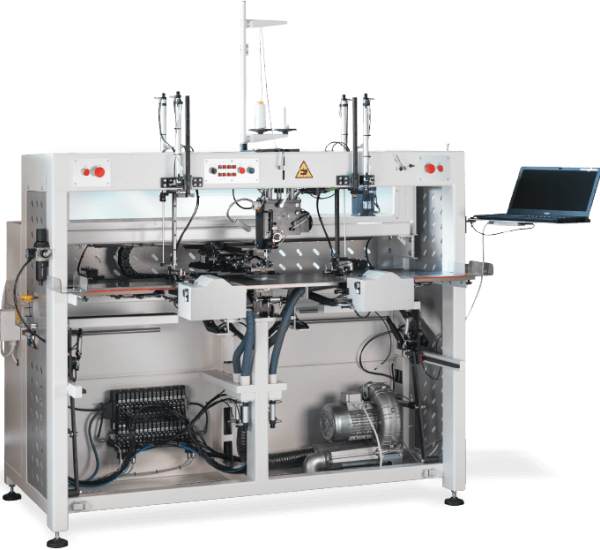

The 1005 unit will fold front and half sleeves, using a vacuum and a pressing system which allow complete precision on the entire length of the crease. After placing the piece with the help of references points, the vacuum system will hold it in order for the operator to fold perfectly the remaining part. Please note that an adhesive system can be added to the machine, if needed. Then, a blowing system will help sending the shirt under the pressing plates for the creasing part. The width can be adjusted from 18mm to 70mm as well as the length, that goes up to 900mm. The cleaning of the suction plates is fast and easy. The machine is also equipped with a stacker at the back, which helps the operator to not waste time after each cycle.

Description

PRODUCT SUMMARY

| Production | 300 pcs/h |

| Electrical Power | 6 Kw |

| Electrical Supply | 380V 50Hz |

| Pneumatic Supply | 7 Bar |

| Air Consumption | 20 l/pc |

| Packing | 140x145x180h cm |

| Weight | 443 Kg |

Reviews (0)

Be the first to review “1005” Cancel reply

Shipping & Delivery

Reviews

There are no reviews yet.