| Production | 300 pcs/h |

| Electrical Power | 1.5 Kw |

| Electrical Supply | 380V+N 50Hzz |

| Air Consumption | 1 l/pc |

| Packing | 190x105x155h cm |

| Weight | 200 Kg |

PRODUCT SUMMARY

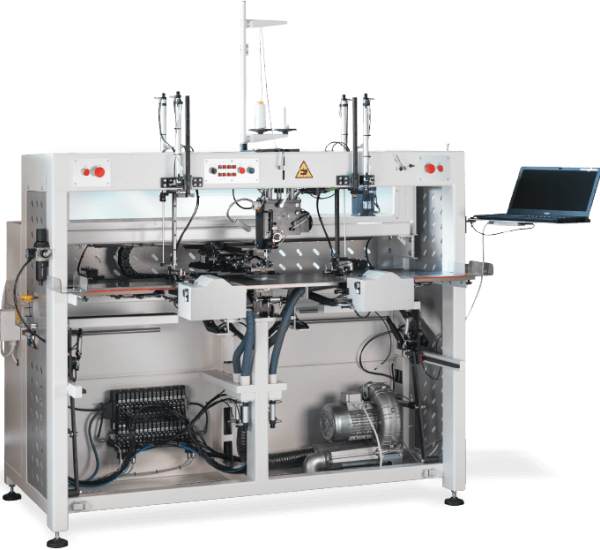

The automatic MCD unit, completed with a single needle sewing machine, was made to sew one or more sewing lines on the pre-ironed front of shirts. The main characteristic is the “easy to use” giving speed and quality results to all different models. During the stitching, a vacuum system keeps automatically the fabric aligned for a perfect sewing line, allowing the operator to work on several machines at the same time. Once finished, the fabric passes under a heated puller to eliminate the wrinkles from the front stip. The width will depend on how the front placket has been ironed and can vary between 0.8 and 30 mm. However, the distance between the border and the sewing line is adjustable by moving the vacuum guide and by changing the foot guide. The machine is equipped with an automated cutting-thread system to separate the different pieces before the stacker. The speeds of the sewing and the conveyor are adjustable electronically.

Reviews

There are no reviews yet.